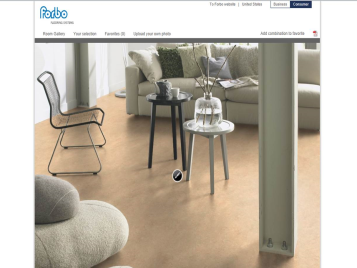

Residential products

Forbo Flooring Systems offers you beautiful, durable, healthy flooring options for your home. Designed to create the interior environment you desire and deserve, let our natural floors inspire you with a broad range of colors, sizes, and applications.